Fort Myers Beach, Florida

GCM Contracting Solutions / ASAR Inc

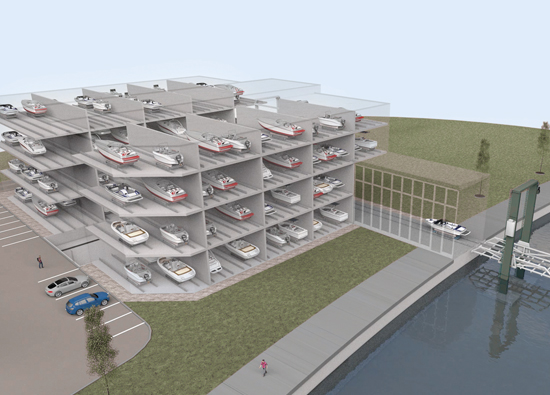

Since 1988, GCM Contracting Solution Inc. has been utilizing the latest technologies to offer the fastest and highest quality commercial construction services in the Southwest of Florida. As a full-service construction company, GCM accompanies projects from conceptualization to completion. In addition to bespoke solutions such as constructing boat or aircraft storage facilities, the company also erects warehouses, offices and factories. As one of the most established design-build general contractors in Southwest Florida, GCM is the premier destination for Tilt-Up and Design-Build developments. Collaborating with this company, we successfully implemented a unique solution for the Gulf Star Marina project in Fort Myers Beach: the first fully automated boat storage facility. In 2020, this project was honored with the Tilt-Up Achievement Award by the Tilt-Up Concrete Association. For 30 years, this award has celebrated innovation, versatility, and beauty in concrete tilt-wall design and construction on an international scale.

Due to the favorable weather and calm waters, Southwest Florida is a particularly attractive destination for boating excursions. There are approximately 38,000 registered boat owners in Lee County alone. Consequently, several marinas in the region are already completely overcrowded. Especially owners of larger boats with a certain height find themselves on never-ending waiting lists for boat slips. In Fort Myers Beach, boats have traditionally been stored in dry racks operated by diesel-powered forklifts. Not only was this method cumbersome, but it was also very noisy. Additionally, there was a need to better protect the boats from severe weather and storms. Since the old system was somewhat outdated, we not only required a secure solution but also one that could accommodate more boats within the same area.

The new storage facility must not only withstand storms and severe weather but also cope with the existing humidity and salt content. The previous system was not only aging but also very rusty due to external influences. Each time a boat was retrieved from storage, rust had to be removed first. Moreover, the location simply requires more space: previously, the storage could only be used with single-depth racks, accommodating 44 boats. Additionally, the demand for storage spaces for larger boats is ever-increasing, with no space available in the existing facility. Furthermore, boats had to be rearranged manually depending on which one was needed next. Hence, the demand for an automated system that autonomously determines the optimal storage position was substantial.

Thanks to the fully automated high-bay storage system, the space can be fully utilized, as boats can now be stored in multiple depths. The 2,964 square meters and nearly 20-meter-high building can accommodate approximately 155 boats simultaneously. Moreover, the concrete structure serves as an absolute hurricane bunker, capable of withstanding wind speeds of over 300 km/h. And the best part? Customers can specify in the BoatCloud app when they need their boat, and the system automatically retrieves the desired boat in time. This eliminates any annoying waiting times for customers. Additionally, the new system is so quiet that boats can be rearranged within the high-bay storage facility even at night, ensuring that those needed next are already in the correct position.