Retrofit

Minimum intervention – maximum effect. This is our motto when implementing a plant modernization. Thanks to our many years of experience in over 600 retrofit projects, we have built up considerable expertise. Regardless of whether individual components need to be replaced, the software overhauled or protective devices retrofitted. As you can see, we are the perfect partner for both system modernizations and expansions. Together we will find the right solution for you. We will bring your system back up to scratch.

When does a retrofit make sense?

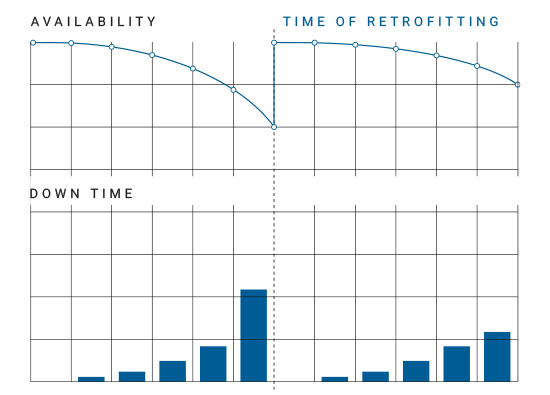

Every system component, whether hardware or software, has its own life cycle. In contrast to steel components, electronic parts in particular have much shorter periods of use. The consequence? The risk of stock failures and expensive production downtimes increases considerably. Malfunctions increase, maintenance costs rise, longer unplanned downtimes are a reality, energy consumption is no longer up to date and protective measures are missing or no longer meet today's requirements. This is where we come in.

Our offer

A partner you can depend on

The experience we have gained in more than 600 successful retrofit projects makes us your perfect point of contact. We're with you from start to finish and provide a full range of services, from consulting and engineering to conversions, recommissioning, and after-sales support. And the best part is that in many cases, our customized system modernization restores availability to the level of a new installation.

Our tailored services

Our customers' needs are our top priority here as well. We take the time to create custom solutions and designs together with you. Our retrofitting team gets to the root of the weaknesses in the system. And our experienced employees not only consider the technical details but also keep a constant eye on the cost-benefit gains. We only start the modernization stage once we have carried out an in-depth analysis of the system. The best part is that the implementation either runs while operation is ongoing, or in stages, where possible to minimize downtimes and allow planning for investments. So in most cases, you only have to do without your overall system for a short time.

Every advantage at a glance

Our goal is to restore the availability of your intralogistics system to the level of a new system, regardless of whether it's from a third party or LTW. In either case, our goal is perfectly clear: we want to enhance the availability of your system. Other advantages you'll enjoy after a system modernization include reduced maintenance costs, guaranteed spare parts availability and supportability of the system, new technological features, and reduced energy consumption, which has a positive effect on the carbon footprint.

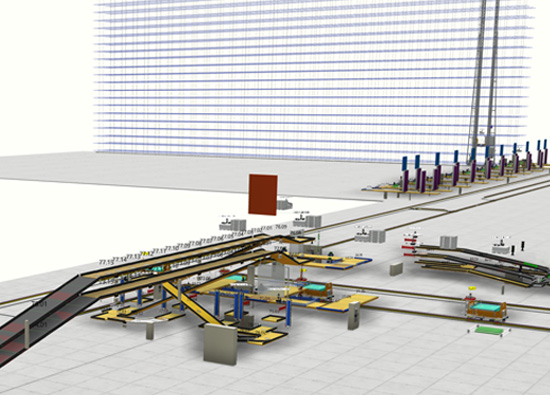

Open heart surgery

Upgrading the old logistics IT to the current state-of-the-art initially feels like open heart surgery. But we would like to reassure you here too: our years of experience are the ideal basis for implementing new software. You benefit from a partner with top-notch expertise, and modern software that significantly boosts functionality. Thanks to our newly developed system simulation, there is the option to first test the changeover on a specially created digital twin. The new system only goes live once all tests have been successfully completed, so you avoid any unpleasant surprises.