Engineers of flow

- Headquarters

- Foundation

- Locations

We are a global, full-service intralogistics provider, and we take our responsibilities seriously. Loyalty and honesty, working together in partnership, and showing respect are our top priorities. To create a legitimate and ethical workplace environment for each other, both we and the Doppelmayr Group subscribe to a code of conduct. A handshake still means something at LTW – you can rely on us to honor our commitment!

Our sustainability efforts go hand in hand with our spirit of innovation. LTW's objective is clear: we minimize negative environmental impact and increase intralogistics efficiency. With innovative, customized approaches, we enable our customers to optimize their processes while simultaneously achieving sustainability goals. Actions to reduce energy consumption or network recovery concepts are just a few examples of how we actively promote the conscientious use of resources and thus the protection of our environment. To express our values, we are represented on the world's leading CSR and sustainability platform IntegrityNext, while also regularly auditing our supply chain regarding sustainability goals and compliance.

Not only do our customers receive turnkey installations – we also do our very best to implement every conceivable solution for them. This is made possible by our vast product portfolio and the ties with our parent company Doppelmayr. Custom-made products are not a challenge, they are our strength. Our expertise, especially on the international stage, plays straight into our hands.

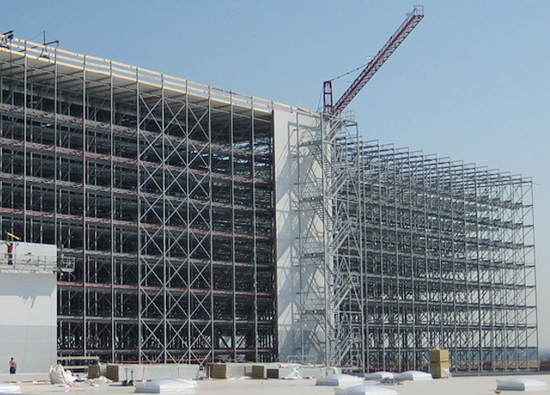

Producing stacker cranes and the components of conveyors in accordance with ropeway standards is one of the stand-out quality features of LTW. We apply the high standards of technology, quality, and safety that are demanded of a ropeway to our products – from the individual transfer cars to the turnkey intralogistics system. Thanks to the use of certified materials, the smallest manufacturing tolerances, and consistent quality assurance in our own production processes, we produce high-quality intralogistics components that ensure every system operates smoothly.

IntegrityNext enables the company to monitor all their suppliers with regard to sustainability and compliance, to meet regulatory requirements and reduce risks. Click here for our IntegrityNext profile

ISO 9001:2015 is the established, globally recognized standard for quality management system certification, and pays special attention to customer satisfaction.

Milestones

LTW BELONGS TO THE

DOPPELMAYR GROUP

Since being founded in 1981, LTW has been a member of the Doppelmayr Group. The global market leader in ropeway construction entered the high-bay warehouse technology market to compensate for seasonal fluctuations in manufacturing and production capacity. Not only is LTW now a mainstay of the group, the company that started out supplying stacker cranes has become an established full-service provider on the international market.